Why Choosing Contract Screen Printing Unlocks Big Benefits for Your Business and Your Customer

Contract screen printing transforms how businesses handle custom apparel orders. Instead of managing printing in-house, you partner with professional facilities equipped for high-volume production.

This approach delivers massive advantages for your business and the people who wear your custom apparel.

What Is Contract Screen Printing

Contract screen printing means outsourcing your apparel printing to specialized facilities. Professional print shops handle everything from art preparation to final production.

You send designs and requirements. They deliver finished products.

No equipment investment. No staff training. No production headaches.

Benefits for Your Business

Cost Savings That Add Up Fast

Contract printing eliminates equipment costs. Professional screen printing presses cost $50,000-$200,000. Add inks, screens, squeegees, and facility space.

Contract pricing beats in-house costs on volume orders. Bulk rates start at $3-8 per piece depending on design complexity.

Your capital stays in core business operations instead of production equipment.

Time Liberation

No production management needed. Contract printers handle scheduling, quality control, and shipping coordination.

Your team focuses on sales, customer service, and business growth. Not ink mixing or press maintenance.

Average time savings: 20-40 hours per large order when using contract services.

Scalability Without Limits

Accept orders of any size. Contract facilities handle 100-piece orders and 50,000-piece runs equally well.

Seasonal spikes become manageable. Holiday orders, events, and campaigns scale automatically.

Growth isn't limited by production capacity.

Access to Advanced Techniques

Professional facilities offer specialty printing methods:

- Discharge printing for soft-hand vintage looks

- Water-based inks for breathable prints

- High-density prints for raised textures

- Simulated process for photographic designs

- Metallic and specialty ink options

These techniques require expensive equipment and expertise most businesses can't justify in-house.

Benefits for End Customers

Superior Print Quality

Professional equipment produces consistent, durable prints. Automated presses ensure identical ink deposits across thousands of pieces.

Colors match perfectly from first shirt to last. Registration stays precise throughout entire runs.

End customers get apparel that looks professional and lasts through repeated washing.

Comfort and Wearability

Advanced ink formulations feel better on skin. Water-based inks penetrate fibers instead of sitting on top.

Professional curing processes ensure prints won't crack or peel. Proper heat application bonds inks permanently to fabric.

Garments maintain their original feel and breathability.

Consistent Sizing and Fit

Contract facilities maintain strict quality control on blank apparel. Size specs stay consistent across orders.

Color matching ensures reprints match original runs perfectly. Important for uniforms, team apparel, and brand merchandise.

End customers can reorder with confidence knowing products will match exactly.

Why Quality Matters in Contract Screen Printing

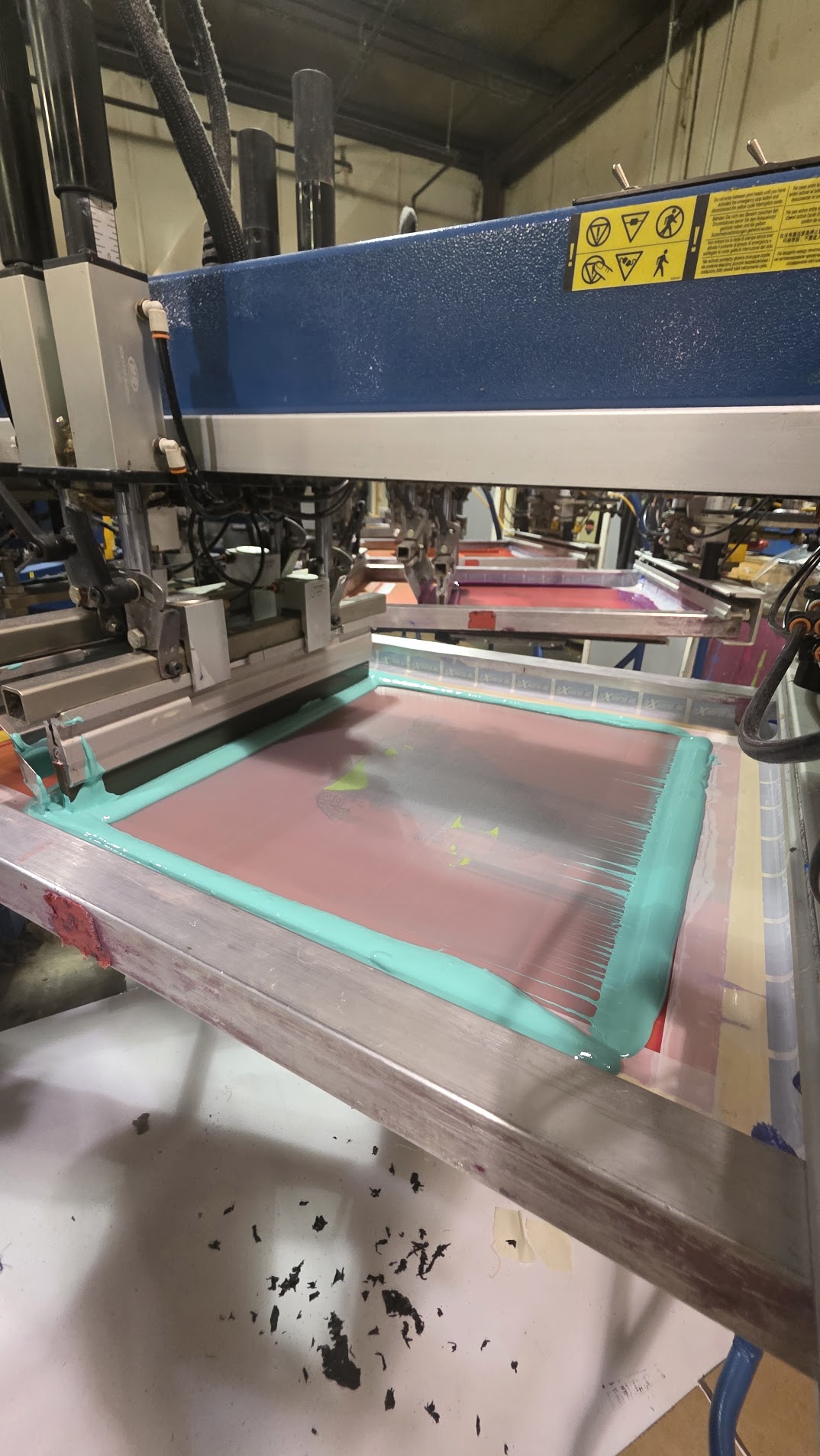

Professional Equipment Makes the Difference

Automatic presses apply consistent pressure and ink coverage. Manual printing creates variations between pieces.

Conveyor dryers cure prints at precise temperatures. Under-cured prints crack and fade quickly.

Color matching systems ensure Pantone accuracy across large runs.

Expertise in Art Preparation

Professional separations maximize print quality. Proper halftones and trapping prevent color bleeding.

Contract facilities optimize designs for screen printing. They catch issues before production starts.

Experience prevents costly mistakes and reprints.

Quality Control Systems

Incoming inspection catches defective blanks before printing. Print samples get approval before full runs start.

Final inspection ensures every piece meets standards. Defective items get reprinted at no charge.

Quality control prevents customer complaints and returns.

Scalability and Volume Advantages

High-Volume Efficiency

Automatic presses print 200-400 pieces per hour per color. Manual printing averages 50-75 pieces per hour.

Volume discounts make large orders extremely cost-effective. Per-piece costs drop significantly on 500+ piece orders.

Multiple press setup allows concurrent production on different designs.

Inventory Management

Contract facilities maintain blank apparel inventory. Popular sizes and colors stay in stock.

Rush orders ship faster when blanks are immediately available. No waiting for apparel shipments.

Bulk purchasing power means better pricing on premium brands.

Geographic Reach

Professional facilities ship nationwide efficiently. Established shipping relationships reduce costs.

Multiple locations enable regional distribution. Large orders can ship from closest facility.

Tracking and logistics handled professionally throughout process.

Fast Turnaround Times

Streamlined Workflows

Automated processes reduce production time significantly. Digital art preparation eliminates traditional film-making delays.

Multiple operators work simultaneously on large orders. Production scheduling optimizes press utilization.

Standard turnaround: 7-10 business days for most orders.

Rush Order Capabilities

Express services available for urgent needs. Rush orders complete in 3-5 business days.

Emergency services handle same-week production when necessary. Premium pricing applies but delivery happens fast.

24/7 production capabilities during peak seasons ensure deadlines get met.

When Contract Screen Printing Makes Sense

Order Volume Thresholds

Orders over 100 pieces benefit most from contract printing. Setup costs spread across larger quantities.

Complex multi-color designs require professional expertise. More than 4 colors need automated equipment.

Tight deadlines favor contract facilities with dedicated capacity.

Design Complexity Factors

Photographic designs need simulated process printing. Gradients and fine details require professional separation.

Specialty inks demand proper application techniques. Metallic, glow-in-the-dark, and puff inks need experience.

Brand-critical color matching requires professional color systems.

Business Focus Priorities

Companies focused on design and sales benefit most. Production outsourcing lets you concentrate on core strengths.

Service businesses avoid equipment investments. Capital stays in revenue-generating activities.

Growth-oriented companies need scalable production solutions.

Making Contract Screen Printing Work

Choosing the Right Partner

Look for established facilities with quality certifications. ISO standards indicate professional operations.

Request samples of similar work. Quality should meet or exceed expectations.

Verify capacity for your typical order sizes. Ensure they can handle peak volume periods.

Communication and Planning

Provide detailed artwork files in vector format. Include Pantone color specifications when critical.

Allow proper turnaround time for quality work. Rush orders cost more and risk quality issues.

Build relationships with account managers. Regular communication prevents misunderstandings.

Contract screen printing delivers exceptional value for businesses and end customers. Professional quality, scalable capacity, and cost efficiency make it the smart choice for serious apparel programs.

Ready to experience the advantages of professional contract screen printing? Contact T Productions today and discover how our automated facility can handle your next custom apparel project with speed, quality, and reliability!